Descripción

Single Side PCB

Single-Side PCB is the simplest and most common type of PCB. It was the first device used for the interconnection and assembly of electronic components forming a cohesive and functional operating system. The primary industry that uses these boards is the consumer electronics industry.

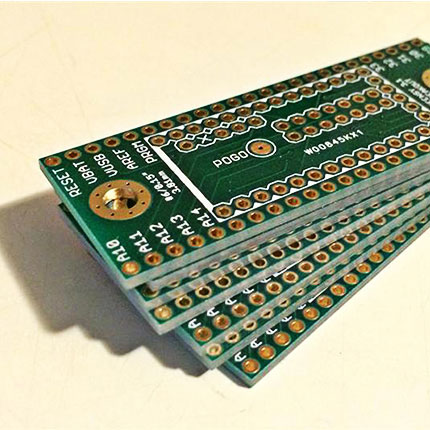

Double Side PCB

Double Side PCB have made circuit in 2 layer of different PCB side that both layer has connect by via PTH (Plated Through Hole) which depend on design this is more complex than Single Side PCB.

Multi Layer PCB

Multi Layer PCB have more layer than double side PCB, it has many circuit layer between Top side and Bottom side of PCB and also each layer can connect with via PTH (Plated Through Hole), this type is more complex than double side PCB.

Gerber file (RS-274-X)

We offer a full range of printed circuit board capabilities to fit all of your PCB needs.Currently we accept 5 PCB file formats ( gerber file, .pcb, .pcbdoc .cam or .brd file format) for PCB fabrication. But if you design your boards with Sprint-Layout software, you can send the .lay6 file to service@pcbway.com for manually generating Gerber files.

- Gerber file format: RS-274-X

- Gerber file naming:

- GTL Gerber top layer

- GTO Gerber top overlay

- GTS Gerber top solder

- GBL Gerber bottom layer

- GBO Gerber bottom overlay

- GBS Gerber bottom solder

- GKO Gerber keepout layer

- DRD Excellon drill file

1.6mm (Default)

1.6mm (Default)PCB Board Thickness

0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm, 2.4mm

Please contact us if your board exceeds these.

Min track/spacing

Min. Line Spacing & Min. Line Width: 4/4mil 5/5mil 6/6mil ↑

Min hole size

0.2mm 0.25mm 0.3mm ↑

Silkscreen

White, Black, None

Finished Copper

1oz/2oz/3oz(35μm/70μm/105μm)

Inner Layer Copper Thickness:1oz/1.5oz(35μm/50μm)

Surface Finishing

HASL with lead,HASL lead free,Immersion gold,Hard Gold ,OSP…

PCBWay Quality control

As the circuit boards are manufactured, and also after they are complete, we subject them to strict tests and checks:

- E-Test

- A.O.I. – Test (Automated Optical Inspection)

- X-ray (check registration accuracy for multilayers)

- CCD – Camera Controlled Drilling

- Impedance control

The testing of our SMD stencils includes:

Real-Time Process Control, monitors the cutting process for every aperture in real time

optical (sight) check

verification of manufacturing tolerances